Why Use Us?

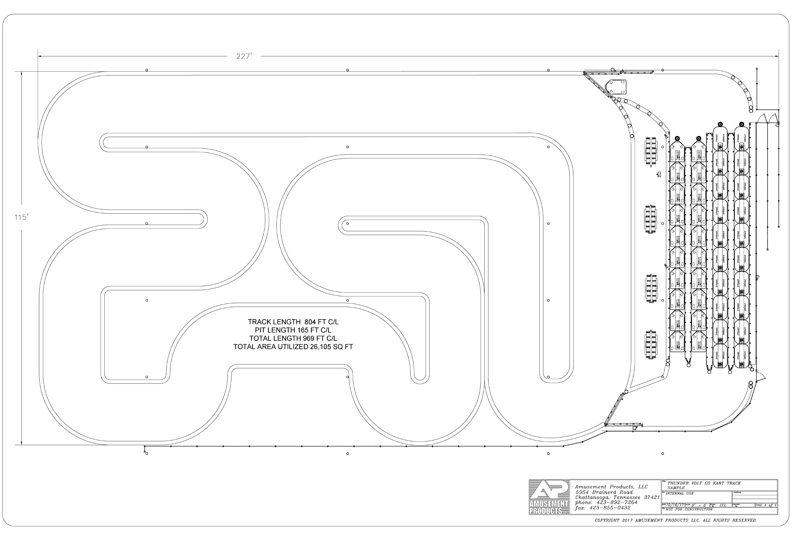

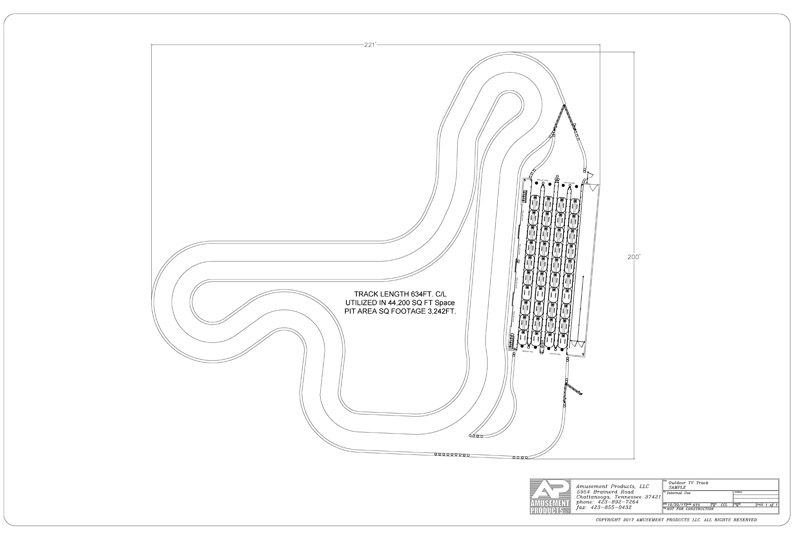

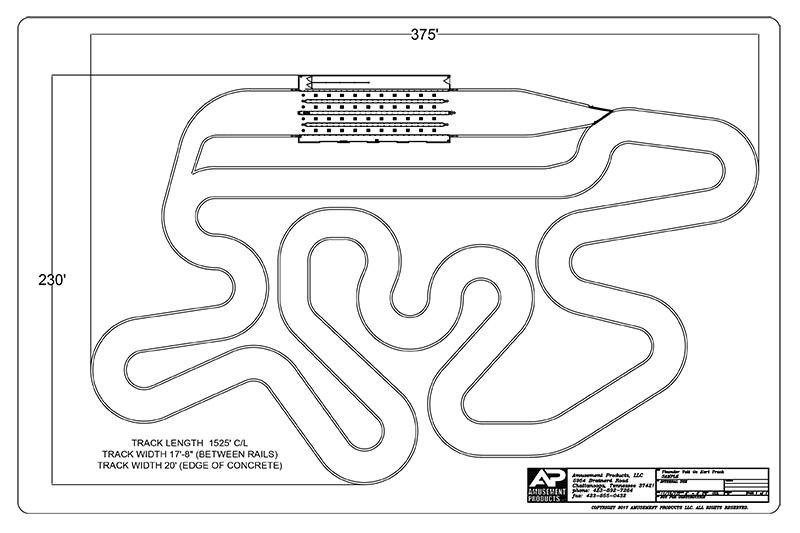

Whether indoors or outdoors, Amusement Construction go-kart tracks push all the limits to make your go kart ride more exciting while keeping your customers safe. Most go karts today will operate just fine on a flat surface track (like an existing warehouse floor), but the track is not interesting to look at and is also less interesting to ride. This results in fewer ticket sales and less profit.

At Amusement Construction we work hard to continually improve our designs and our construction methods to build a better go-kart attraction. We start by adding different elevations to the track (up to 8 feet for slab on grade tracks) to add a vertical dimension to the track. Next, we bank the turns 1 to 4 feet to add an additional dimension for the racers. The end result is a go kart track that not only looks amazing, it is an unbelievable ride!

The quality of construction is equal to the superior design of our tracks. We use special tools to make the ride smoother than any go-kart track you would ride anywhere else. Since commercial karts have no suspension system, a rough track is a terrible ride. Using precision concrete place and finishing techniques, our go-kart tracks are smoother and safer than any other track built today. As a potential track owner, you should realize that a go-kart track is the best it will ever be the day it is poured and finished. Done wrong, and the only solution is to tear it out and start over. Amusement Construction gets it right the first time!

The end result is a superior race, ride and experience for your customers! This will mean more ticket sales, happier customers, more repeat rides and more profit for your go-kart attraction.

But that is not all we do. Since we design and build go-kart tracks – as well as operate them – we constantly research ways to save you money and make new tracks better. We are the only major go-kart track builder to improve the safety barrier systems and pit designs over the last 20 years. Now on our third generation track rail design, it is important to note that we created the first tire and steel rail safety barrier system in 1980. While effective, it needed improvements to reduce kart damage and increase rider safety.

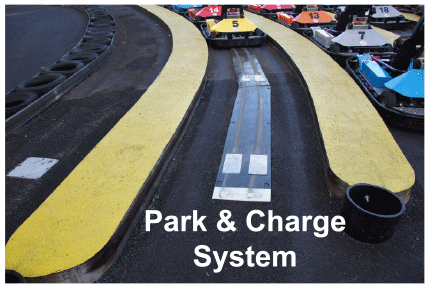

Today we use primarily a plastic barrier system with a plastic, impact-absorbing rail buffer. The motivation was to replace the tire and steel rail with something that would be cleaner (not a breeding ground for mosquitoes), impact-absorbent and require less space.

For indoor tracks, space is a premium. When first gas – and now electric – indoor tracks became more popular, finding ways to conserve space and keep the customers safe was a key goal. Furthermore, the impact on steel rails by steel bumpers make a lot of noise, especially indoors. Working with Amusement Products LLC, Amusement Construction Co. developed a plastic face for the rail system, using a special plastic that is extremely flexible and fracture resistant. The all-plastic barrier system is cleaner, more compact and quieter than the traditional tire and steel rail system. As steel prices have increased over the years, this has become a less expensive alternative!

By supplying the equipment and the construction of the attraction, we can help you get your project started and opened in the best possible way.